Nevada has valuable geothermal resources. The drilling technology that Nevada projects use today is more about accuracy than brute force. Modern rigs, bits, and planning help operators get to zones faster while keeping land and water safe.

More Precise Wells and Stronger Tools

Directional drilling and downhole motors let wells follow specific paths through hot rock and porous formations. This cuts down on extra footage and directs the borehole to where heat or hydrocarbons are easiest to get to. Polycrystalline diamond compact bits, better mud systems, and stronger casing design all help to reduce wear and the chance of getting stuck in a pipe. Advanced drilling NV teams use geologic modeling and trajectory control to make fewer wells produce the same amount of oil.

Using Data to Drive Drilling Increases Uptime

Sensors along the drill string keep track of vibration, temperature, torque, and pressure. These signals tell the software to change the weight on the bit and the speed of the rotation to keep the drilling steady. Predictive maintenance warns you about pumps and bearings that are about to fail before they do. These improvements in efficiency cut down on downtime and increase capacity, especially on geothermal wells where high temperatures put a lot of stress on equipment.

Better Efficiency Helps Make Production More Reliable

Faster drilling cycles mean that you can connect to power plants or gathering systems. Long-term flow is also better when well quality is consistent. This keeps the energy supply stable during seasonal demand swings. For geothermal, better wellbore integrity and zonal isolation can make the field last longer and cut down on the need for rework. For oil and gas, putting wells closer together and making sure they are clean can reduce surface disturbance and lower operating costs.

FAQs

What kind of drilling technology do Nevada operators use the most?

Directional drilling, high-performance bits, real-time sensors, and automated rig controls are all very common.

How do improvements in efficiency affect costs?

They cut down on time that isn’t productive, lower the number of tool failures, and lower the number of wells needed to reach a production goal.

Is advanced drilling NV helpful for geothermal?

Yes. Tools with a high temperature rating and better trajectory control make it more likely that things will go well and keep the well safe.

Does better drilling have less of an effect on the environment?

More accurate wells and fewer moves of the pad can make the surface area smaller and cut down on the number of trucks on the road.

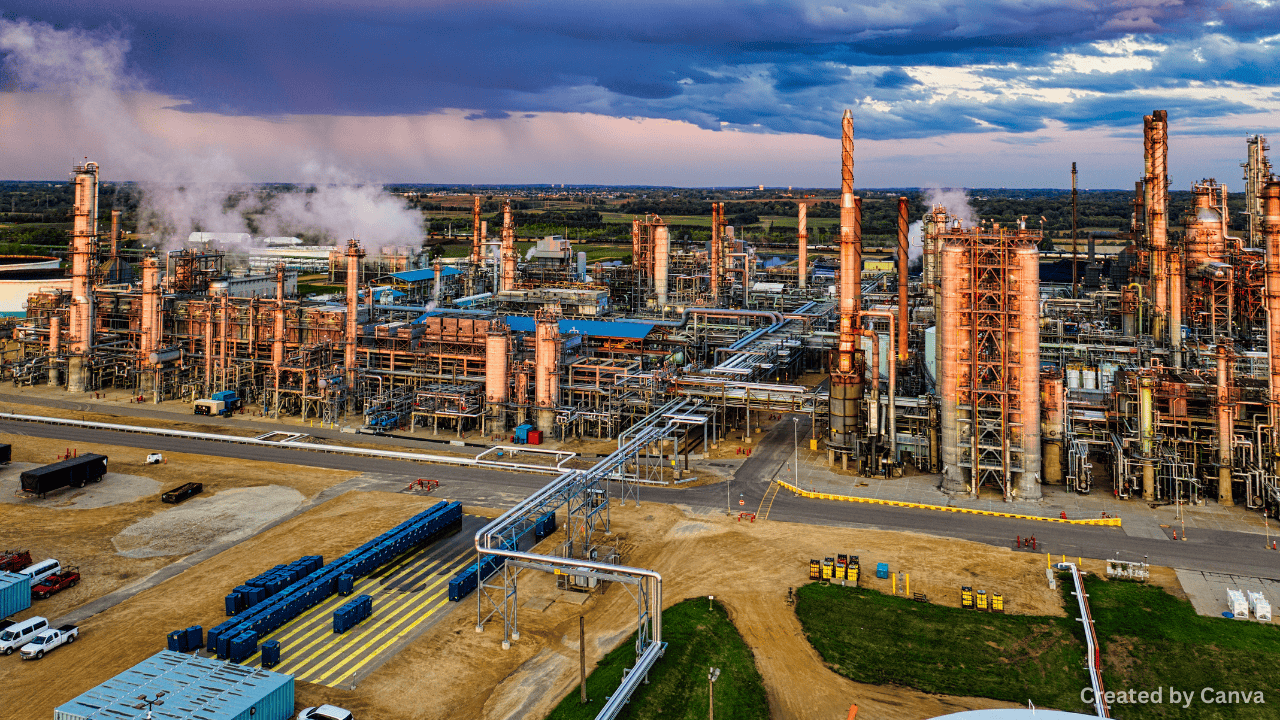

Featured Image

Images are by Canva.com